Richard worked in Europe advising independent watch manufacturers as a technical expert and helped with fine tuning of some of the products we see available today as an experienced micro machinist and prototype developer, process engineering advisor. We are not able to mention the companies due to contract agreements. In 2015, founder of R. McMahon Watchmakers, Richard McMahon has embarked on a continuing journey: manufacturing Australian-made timepieces in Adelaide, with movement parts manufactured in-house for custom built movements. Cases are currently being manufactured on equipment in the R. McMahon in the Tonsley Innovation District and Mawson Lakes micro machining centre, South Australia and our design studio and UniSA and Adelaide University Mawson Lakes micro fabrication facility, partnering with the Future Industries Institute and Australian National Fabrication Facility as an Industry Representative. An exclusive list of clients has been invited to collaborate on this project with Richard. Each client will inform the aesthetic outcome of their watch – the design of the dial in hand-made enamel or precious metal, the watch hands and the size and shape of the case based on their own preference. Richard McMahon tourbillon, quarter repeater and in-house chronographs on offer, it can be expensive work, but having a watch on your wrist knowing it is one of a kind, is something pretty cool. We have completed as consultants calibres for final design and prototyping for some large companies in the ultra high quality end of the market, we estimate a few thousand watches manufactured are on peoples wrists unaware Richard McMahon was involved in the development of these special watches. In the last 12 months we have designed, manufactured and shipped over 14 watches to watch collectors. In the last ten years more than 20 watches have been delivered or exported. We have been quietly in the last 10 years been developing 2 new totally Adelaide, South Australia manufactured watch movements. We are introducing these to our new custom watch offerings. Richard McMahon, master watchmaker is offering to manufacture a completely custom watch to a customer’s specification, custom complications on request, in-house enamel dial manufacture and engraving to ensure the finished product is a world-class timepiece, native to its place of manufacture in Adelaide, South Australia. Helping to bring design, innovation and manufacturing back to South Australia. This is a rare combination of skills globally to have in one workshop, case, hands, movement and enamel dial manufactured by one master watchmaker, Richard McMahon.

Contact us regarding custom personalised Australian manufactured watch.

Please message for appointment times - info@rmcmahon.com.au

0404117186

0403586850 text for appointment

(Please text your question instead of leaving a voice message)

By appointment only.

Stainless steel and Argentium silver cases hand made in our Tonsley Innovation District workshop and AdelaideUniversity (UniSA) Micro Engineering Workshop. Watch dials hand made in our workshop in enamel, silver, gold, Lapis lazuli. Custom made hands. Manual wind, automatic and chronograph models made to order. We are now concentrating making custom manufactured watches starting at $25,000 for basic modified custom movements. In-house bespoke manual wind manufacture calibre starting at $50,000 in stainless steel.

Dial blanks hand cut, here in Adelaide, South Australia.

South Australian opal localy cut and polished. Malachite and mother of pearl cut and polished in our workshop for our custom watch manufacture. Matching hands manufactured in-house.

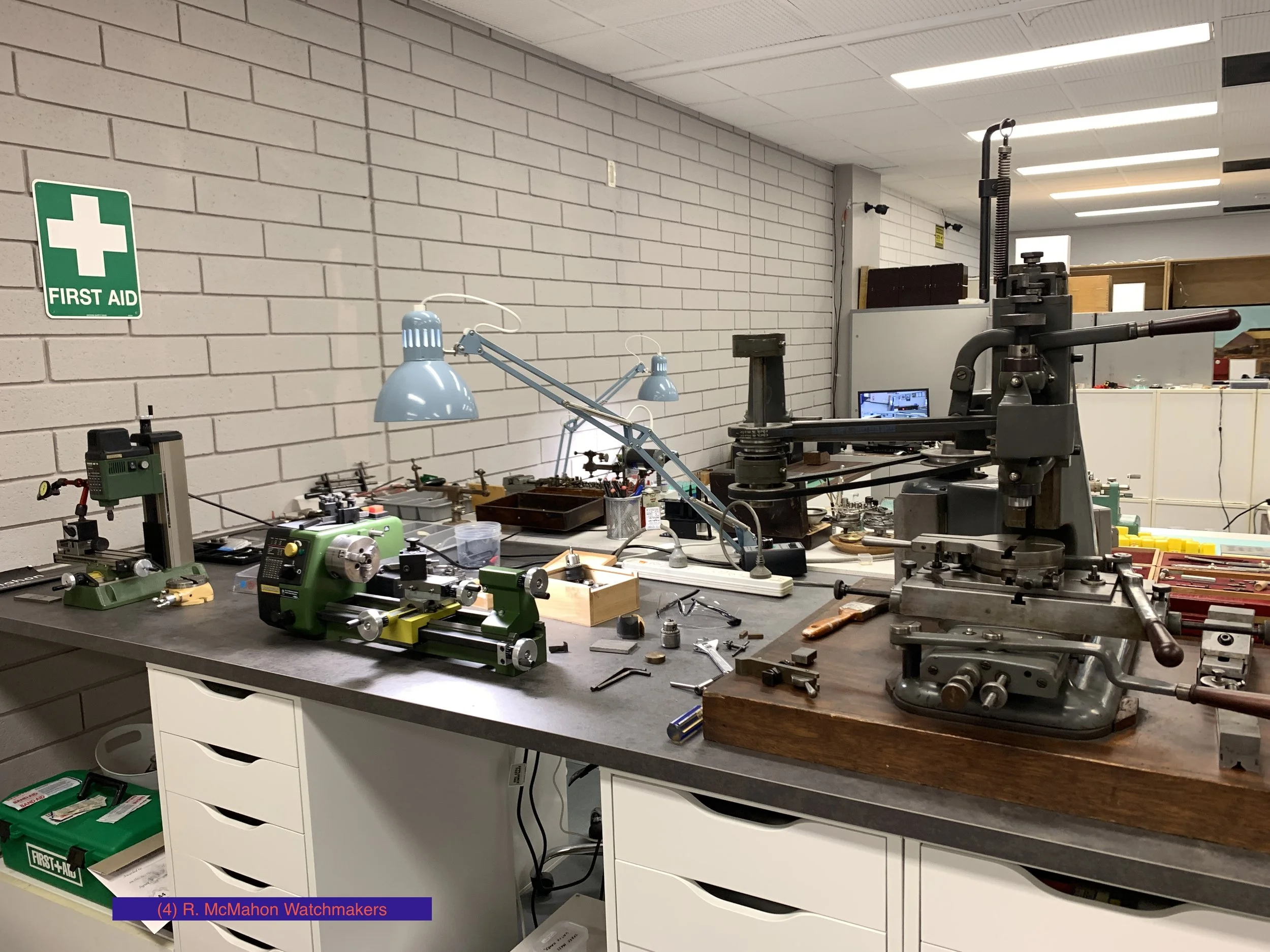

We have a rare mix of capabilities at R. McMahon Watchmakers and McMahon Micro Machining. Machinery like the Henri Hauser precision milling machine constructed to manufacture parts in the 1940’s for companies like Patek Philippe and Rolex. To modern CNC machines for precision miniature parts. We have the capability to manufacture our own watch cases and precision watch movement parts. In most cases the same machines used by the top factories and independent watchmakers in Europe. Along with hand made enamel watch dials made personally by Richard McMahon, it is indeed a rare facility with this combination of machinery and skills. We offer small volume prototype machine design and manufacture in-house for the medical, aerospace and defence industries. For watches we manufacture in house wheels, pinions, main plates, bridges, regulators, balance wheels, pallets, escape wheels, barrels and other movement parts to manufacture custom movements in house in Australia.

Precision manual machining is still used by Richard McMahon for rapid prototyping for testing for medical and defence if a one off piece is needed for testing. Sometimes manual machining can be faster than setting up and running CNC. We have both systems, we just weigh up speed, cost and accuracy required for the best outcome for our clients. We are on of the few micro machining workshops offering both precision systems in the one company. Very rare in Adelaide, South Australia.

Dials manufactured in Silver, gold or copper. Hand made enamel dials made personally by Master Watchmaker Richard McMahon in custom colours in our workshop at the Tonsley Innovation District, South Australia. Richard McMahon is one of only 3 independent master watchmakers globally able to manufacture in-house movements, hand made enamel dials, cases and hands. And then with complications on offer makes his workshop incredibly rare globally. True custom made rare one off master watchmaking.

Two tone matte blue and white enamel dial on sterling silver. hand made by Richard McMahon. We manufacture in custom colours, gloss or matte.

Dial flange with holes drilled to be tapped for hand made hour markers. Richard McMahon personally machining these parts, on site.

Custom manufactured pocket watch, at the mid-point of manufacture. In-house enamel dial made by Richard McMahon. Bespoke maritime style hand made stainless steel case for client. (pre-engraving). Suspended hour indicator battons. An example of in-house manufacture.

Hand made enamel dial, case and hands by Richard McMahon in his Tonsley workshop, Souh Australia. Richard McMahon personally manufactures each enamel dial. For yhis custom military/industrial style one off custom commission Richard McMahon elected to manufacture the case on manual lathes snd milling equipment, from 316L stainless as specified by the client. For some manufacturing it is more efficient to use traditional machines rather than a CAD drawing, machine set up and CNC run time. For more complicated cases with flat, complex features and threaded case backs Richard McMahon will create a CAD drawing, export a file to a selected 3, 5 or even 8 acis milling machine. Having that choice and personal control gives R McMahon Watchmakers the creative edge to complete very complex modern and traditional designs. By the way the client was delighted with the finished watch, it was a very special and personal gift to himself.

In house prototype being tested before new balance wheel and regulator manufacture, movement finish in grey, blue, yellow or rose gold and rhodium. It is a rare thing movements being manufactured in the Southern Hemisphere. We at R. McMahon Watchmakers a rare manufacturing workshop building our own movements, not just importing parts and labelling as Australian Made.

We manufacture our own enamel dials in-house at our Tonsley workshop in South Australia. These are test colours fir colour matching. We matched an enamel dial here to a clients Porsche colour paint. We got a near perfect match in gloss enamrl with a depth of colour matching his 911 SC classic. (Stunning car by the way). Richard McMahon may test fire 2 or 3 Stirling silver plates to get the colour correct and chart temperatures and kiln time. This takes many years of practice and experimentation. Each one is an individual work of art. We believe only 2 workshops glibaly have a master watchmaker able to manufacture a movement, case, hands, enamel dial and other essential parts that are fabricated within the same studios by the same master watchmaker. With over 35 years experience manufacturing all watch parts for restoration work as an expert and slowly iver the last 20 years building these individual disciplines within one watch has been a many thousands of hours journey, but worth every second because Richard McMahon loves beautiful watches.

Sterling silver matte finish enamel dials hand made by personally Richard McMahon in our Tonsley workshop. Series 1 manual wind shown here. First series pre-sold, complete and delivered. Hand made watch case. With screw on back, sapphire crystal glass.

Hand made enamel watch dials made in-house by Richard McMahon.

Manual wind prototype with custom manufactured parts being tested, an early stage before custom regulator and new drive wheel and main plate was manufactured in-house by Richard McMahon. We still offer hand made cases and dials with heavily modified Swiss movements, but our main focus going forward is our in-house movement manufacture. This series Tonsley has already sold and delivered ahead of schedule. We have a track record of manufacturing very complicated in-house parts, wheels, pinions, manipulates and bridges. Chronograph levers, springs and wheels hand made by master watchmaker Richard McMahon. Date and calendar disks machined, engraved and printed in house with jumper springs and day/date wheels and cams made in house by R McMahon. Toubillon carriage, pinions and lever pallets manufactured and assembled in our micro precisiin machine centre in South Australia, designed by Richard McMahon to exacting specifications. Our own balance wheels and escapements. As with any watch manufacturer off the shelf jewels are purchased and then modified to custom shape and fitting. We still purchase hairsprings and modify for our own purpose and technical requirement, this is the norm even in master watchmaking workshops around the world. It is in these cases not a matter of purchasing parts and fitting them, many hours of R & D and testing still is required for our in-house movements. Richard McMahon is currently completing prototyping on a rare alarm and repeating design with him manufacturing by hand the gong and sounding bell with hand polished hammers and gearing system. We believe this will be a first in the Southern hemisphere and matches with an enamel dial hand fired by McMahon very rare globally as a combination.. We are not aware of any watch manufacturer globally at 100% content in custom manufacture. We strive to get as close to 100% as possible with only the same limitations ad lhe largest most established watch manufacturers. We are regularly asked to respect our watch collectors privacy snd publish photos of completed watches if requested. Some serious collectors prefer to remain anonymous and have their name added to the finished custom watch. We are happy to keep these relationships private. We are used to operating under NDA’s for our micro machining work for industry as we have for decades. Own a rare custom made wristwatch made in house in Australia knowing nobody else has the same custom made watch by Richard McMahon. Our most basic watches still start at $25,000 for the next few months. From December this year we will be only offering one off custom Richard McMahon manufacture. Timepiece with enamel dial will start at $50,000. Alarm or chronograph will start at $85,000 with hand made enamel. Other combinations will exceed $120,000. Build times start at 3 months from deposit payment for timepiece with enamel dial and complications like date and day models currently 6 to 9 months. Full custom complications like Toubillon and chronograph approximately 9 to 12 months depending on complexity and our other order list. A deposit on proceeding with full design work and starting manufacture requires a 30% to 50 % deposit depending on the build and materials required. A design book with CAD technical drawings and manufacturing photos of tour watch are supplied on completion. A workshop tour on signing to proceed and a tour near final assembly stage is welcomed unlike other master watchmaking workshops. Existing clients only are permitted by appointment for privacy and safety reasons, we also observe high standards of cleaning and some areas are restricted as our cleanrooms are viewable through glass but not accessible without a dust suit.

Cases hand made in our workshop based in Tonsley South Australia and Mawson Lakes South Australia. Stainless steel, titanium, silver, gold and aluminium on manual lathes and mills.. Wilemin-Macodel 8 axis CNC machine milling and DMG Mori 3 axil and multi axil FAUNC Robodrill alongside manual hand finishing in Richard McMahon’s micro machining workshop McMahon Micro partnering with ANFF and the Future Industries Institute Adelaide University as an Industry Representative. These cases are some of our prototyping cone in-house on manual machines at our Tonsley workshop and test cases for our new mechanical alarm and calendar complication model.

Custom built pocket watches starting at $25,000. Wrist manual wind chronograph with in house manufactured case and enamel dial starting at $25,000.

Note, Tonsley Watches are no longer available. All have been allocated and pre-sold. We still offer our one off custom watches.

R. McMahon custom.

Our first series introductory prices have all been allocated, and delivered ahead of schedule.

Changes and alterations will be charged accordingly.

Precision large manual mill used by Richard McMahon for case and tooling manufacture. Sometimes big machines are needed to make small precision watch parts. Our machinery is distributed between our micro machining centre McMahon Micro with the ANFF Adelaide University in Mawson Lakes and our prototyping and testing facility at the Tonsley Innovation District.

Willemin-Macodel precion 8 axil mill for making main plates, movements, bridges, wheels and pinions and escapement parts. We manufacture balance wheels and escapement parts, hand finish and spend many hours assembling, testing precision and surface finish on the OLS 5000 to ensure accuracy. Micro machining centre for the same level of manufacturing as the Swiss, German and Japanese manufacturers, simply because we use the same machines. We actually manufacture in Australia, not importing cases and dials from Germany or Asia as other companies do. Workshop tours organised of our Mawson Lakes and Tonsley facilities for clients proceeding with custom manufacture. See the real deal in Australian watch manufacture. Master watch maker Richard McMahon. Our combination of in house movement, case, hands and enamel dial manufacture is VERY rare anywhere in the world.

The Robodrill is a great machine for manufacturing complex profiles and shapes for case manufacture, once the general case shape is complete, Richard McMahon will either polish or satin finish the case, complete strap attachment holes and either thread for a screw back or other custom case back fittings. We manufacture is solid or exhibition backs with a sapphire crystal, depending on requirements. Watch movement main plate blanks manufactured on this machine and transferred to the precision Wilemin-Macodel multi axis machine for jewel holes and pockets for wheel and lever fitting. Every machine is important and each precision process checked for quality on the OLS 5000 before proceeding to the next step. This is done here in the he machine centre, Richard McMahon does not import cases, he makes them.