R. MCMAHON WATCHMAKERS

Richard McMahon – Independent Master Watchmaker

Vintage Rolex & Omega Watch Service, Repair and Restoration in Adelaide

Richard McMahon – Independent Master Watchmaker

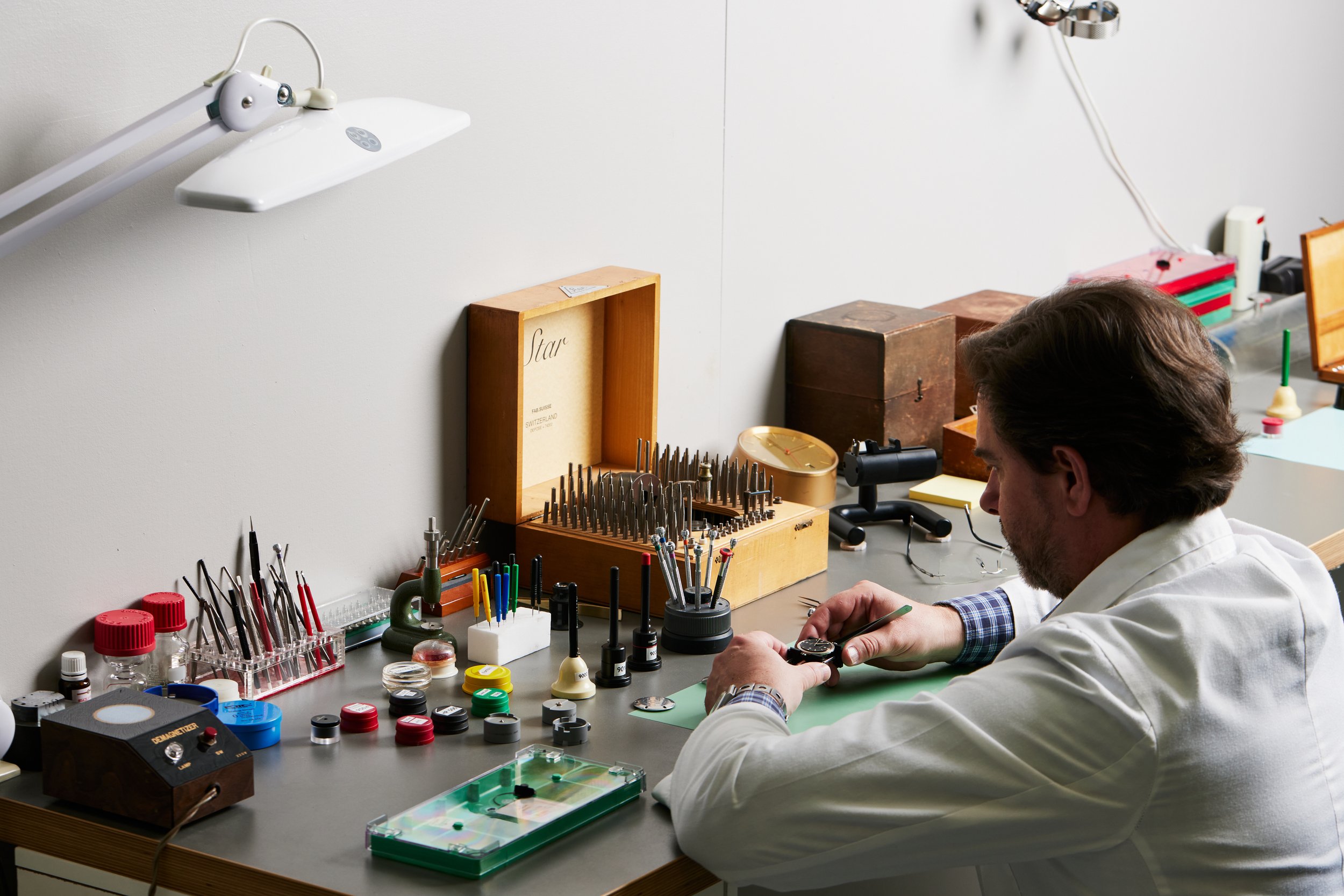

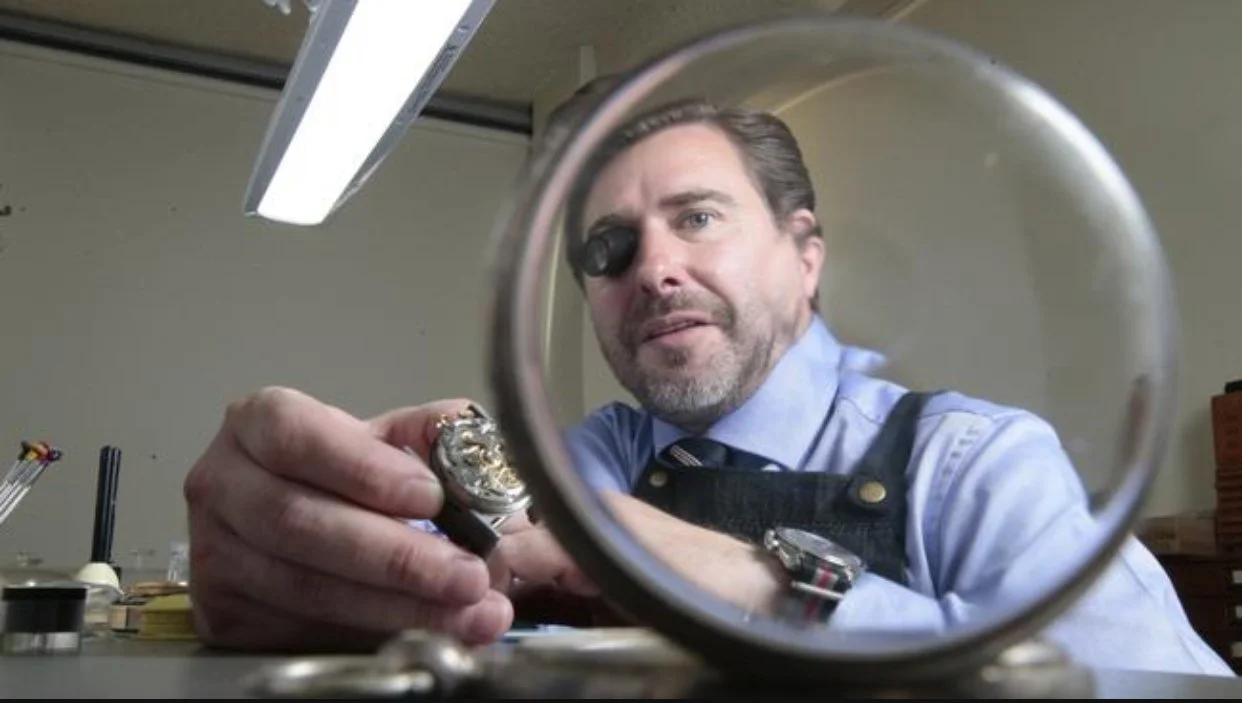

R. McMahon Watchmakers is an independent Adelaide-based workshop specialising in the service, repair and restoration of vintage Rolex and vintage Omega timepieces. Led by Richard McMahon, an Australian Master Watchmaker with extensive European restoration experience, all work is performed personally, in-house, and without outsourcing.

Based in Adelaide, South Australia, the workshop provides specialist Rolex and Omega restoration for collectors, enthusiasts, and owners of historically significant watches. Each timepiece is assessed and serviced using sympathetic, historically correct methods that prioritise originality, mechanical integrity, and long-term value.

Vintage Rolex & Omega Specialist for Collectors and Heirloom Timepieces

R. McMahon Watchmakers is not a general watch repair shop. We specialise exclusively in the restoration and full mechanical servicing of collectible vintage Rolex and Omega watches for clients across Adelaide and South Australia.

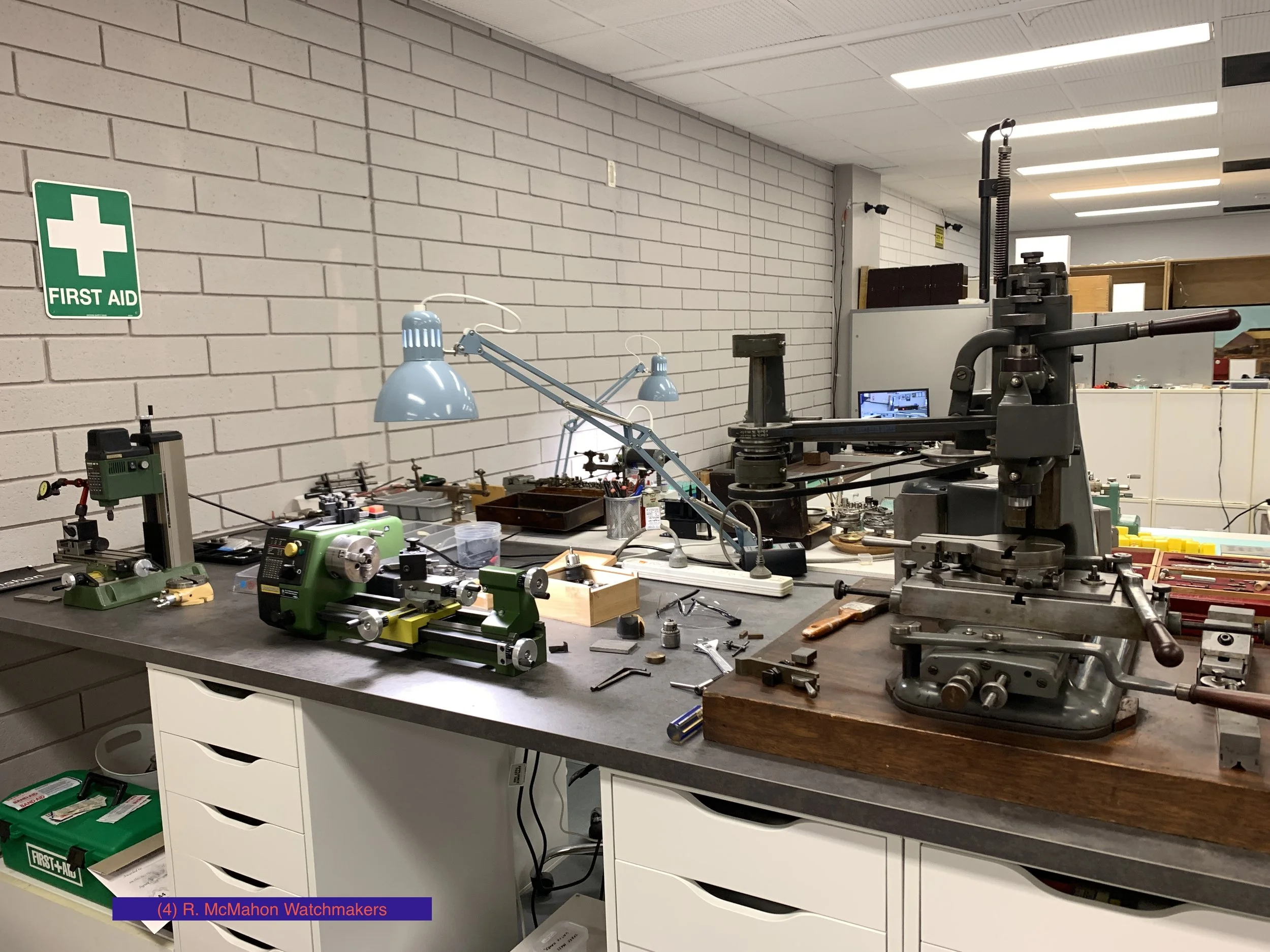

Our work focuses on complete movement overhauls, preservation-led restoration, and the in-house manufacture of discontinued or obsolete components using precision micro-machining techniques. Unlike standard service centres, restoration decisions are guided by collector standards rather than replacement-driven processes.

Every Rolex and Omega entrusted to the workshop is personally evaluated and serviced by Richard McMahon, ensuring consistency, accountability, and craftsmanship at every stage.

Accepted Vintage Rolex & Omega Models

We currently accept:

Vintage Rolex full-size models manufactured prior to 2015

Vintage Omega watches manufactured prior to 1971

All restorations and full services are performed independently, in-house, using traditional horological techniques and sympathetic restoration principles. Full pricing details are available on our pricing page.

Appointments are strictly limited and by request only.

True In-House Watch Manufacture

Beyond restoration, R. McMahon Watchmakers is one of the very few independent workshops worldwide engaged in true in-house watch manufacture.

Every commissioned timepiece is designed, engineered, and hand-crafted in Adelaide, South Australia — from original movement architecture to precious metal cases and hand-made Grand Feu enamel dials. Each project reflects thousands of hours of design, machining, and traditional watchmaking expertise.

Richard McMahon personally manufactures:

Mechanical watch movements

Watch cases

Grand Feu enamel dials

Over 90% of all components in Richard’s premium in-house movements are manufactured internally. Only industry-standard items such as jewels, hairsprings, mainsprings, and select pinions are externally sourced — consistent with the practices of the world’s most vertically integrated independent manufacturers.

Micro Machining & Advanced Engineering

Richard McMahon is also a specialist in precision micro-machining and advanced engineering, operating McMahon Micro Machining alongside his horological work.

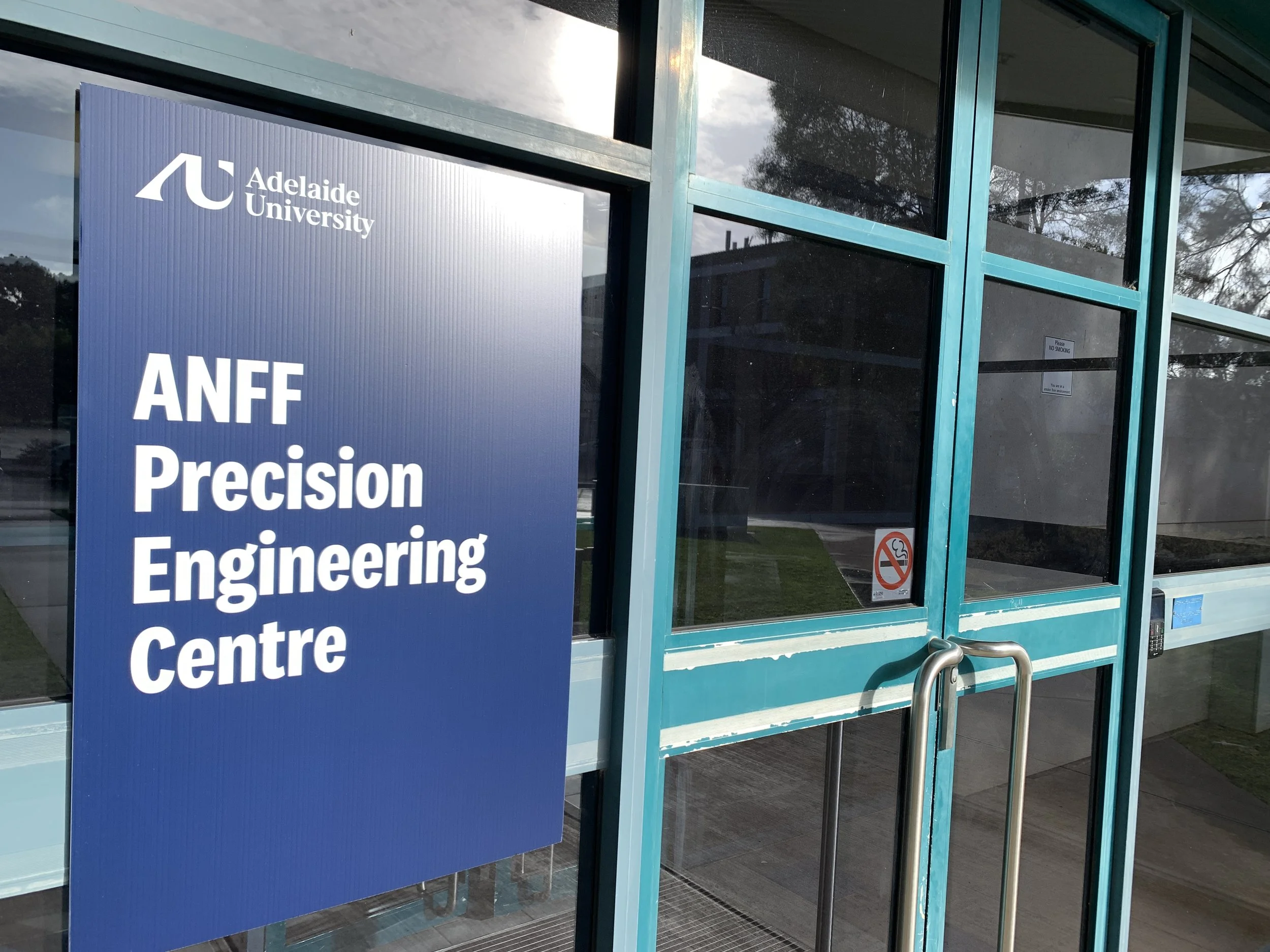

His experience extends into medical, aerospace, and precision device manufacturing, including complex component manufacture, assembly, and testing. Richard has worked extensively within the Tonsley Innovation District, University of Adelaide, and UniSA Mawson Lakes workshops and laboratories.

He is a:

Micro Machining Industry Representative to the Future Industries Institute, University of Adelaide

Contributor and speaker for the Australian National Fabrication Facility (ANFF-SA)

Speaker at the UniSA Microengineering Winter School

This advanced manufacturing background directly supports the restoration and manufacture of complex mechanical watches where precision, tolerances, and material knowledge are critical.

Independent, Australian, Bespoke

Every watch serviced or manufactured by R. McMahon Watchmakers reflects a commitment to independent Australian horology. Each project is bespoke, combining traditional watchmaking principles with state-of-the-art micro-engineering — genuinely building watches and movements in Adelaide, South Australia.

Richard McMahon MAICD is an independent master watchmaker bringing advanced manufacturing back to South Australia, one watch, one movement, and one restoration at a time.

Appointments are strictly limited and available by request only.